Sterility Assurance

Thermal Validation

a) Validator

Kaye Validator AVS Advanced Validation System

Advanced Validation Technology

The Kaye Validator AVS (Advanced Validation System) combines accurate sensor measurements with all GMP requirements for calibration and traceability to national standards, while generating compliant reports and managing the validated assets and validation equipment. The Validator AVS offers improved hardware features, an easy to use data handling concept and an intuitive, user-friendly software interface.

Thermal Validation System – Kaye Validator 2000

The Kaye Validator® simplifies the entire validation process by reducing setup time, minimizing sensor handling, automating sensor calibration, neatly organizing study data and generating regulatory required reports. It comes with a comprehensive 1-year warranty and is supported by fully validated hardware, software and firmware documentation.

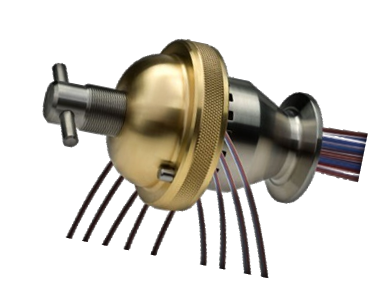

Feedthru for Autoclave Applications

Easy way to seal the autoclave port when introducing thermocouples into the chamber. Standard 1.5” TRICLAMP ® process connection. Installation is simple with out the need of any tools, fitted with safety release mechanism.

- Accommodates from 1 to 18 thermocouples of any (or varying) diameter

- No threads or sharp edges to damage thermocouple wires

- No hole plugs required for unused t/c ports

- Accepts labeled thermocouples

- Simple and inexpensive silicone rubber sealing gaskets

- Standard 1.5″ tri-clamp connections

- Easily installed with no tools required

- TUV certified for pressure vessels from -1 bar /+5 bar, and -60°C / + 160°C

b) ValProbe

Kaye ValProbe Freeze Dryer Logger

Ultimate design for Freeze Dryer and Cryo application up to -85C with flat measuring surface to maximize thermal response time and accuracy of measurement. Long battery life at extremely cold conditions.

Kaye ValProbe® Cryo Temperature Logger with thin and very flexible sensor

The new Cryo Logger with the very thin and flexible tip is the perfect datalogger for an extended temperature range from -85°C to +140°C. The Logger provides a single solution for a variety of applications, such as cryogenic chambers, Lyophilizers, ultralow freezers and other deep temperature applications and high temperature applications.

c) RF Wireless

Kaye RF Valprobe Validation System

The Loggers are designed for operation in warehouses, chambers, fridges and freezers. Loggers have internal RH sensor and either an internal or external temperature sensor. There is an option to read 4/20mA, 0-10v or contact switch inputs.

- Internal RH Sensor: Range 0-100%RH, Accuracy 2%RH

- Internal Temperature: Range -20°C to 60°C, Accuracy 0.5°C

- External Temperature: Range -200°C to 200°C, Accuracy 0.1°C to 0.3°C

- Battery Life: e.g. 2 years @ 1 min sample rate

The loggers store up to 10,000 samples per sensor permitting the operation as a data logger if RF communication is not possible, e.g. one logger placed in a warehouse exhaust HVAC duct. The logger will resume transmitting data once it is in RF communication with the base station or other logger.

Microbial

a) Air Sampler

MiniCapt® Mobile Microbial Air Sampler

- Glove-compatible touchscreen

- Intuitive user interface

- HEPA filter exhaust

- Remote connection to the BioCapt Microbial Impactor (Single-Use)

- Autoclavable with a sanitizable enclosure

- Available in 12 languages

MiniCapt® Remote Microbial Air Sampler

- Intuitive user interface

- HEPA filter exhaust

- Remote connection to the BioCapt Microbial Impactor (Single-Use)

- Autoclavable with a sanitizable enclosure

- Available in 12 languages

Surcapt Microbial Surface Detection Kit

- Optimize Time

- Automatic Reading

- High Sterility Assurance Level Guarantee

- Able to detect organism within a sample, bringing the sampling sensitivity to a new level

BioCapt® Single-Use Microbial Impactor

- Complies with ISO 14698-1

- Culture media validated to be

stored either at room temperature or under refrigeration, with a shelf life of up to nine months - Offered in standard culture media of trypticase soy agar (TSA) and sabouraud dextros agar (SDA), as well as client-specific, pre-validated microbiological culture media

- Compatible with leading active air monitoring systems

Microbial for Compressed Gas Kit

The Compressed Gas Sampling Kit allows effective monitoring of air in compressed gases for the presence of viable microorganisms.

b) Real Time Monitoring

BioCapt® Microbial Impactor

- Stainless steel

- Protects petri dish from unintnetional contamination Vacuum draws air down over media for sample collection

BioLaz® Real-Time Microbial Monitor

- Capable of single BioCount detectionrepresentative of one colony-forming unit (CFU)

- Validated to USP 1223 and EP 5.1.6 requirements

- Not constrained by physical and biological efficiencies associated with impact air samplers

- Not constrained by the type and quality of the growth media

- Real-time, continuous counting free from error sources, including: contamination, mishandling and inaccurate counting

- Easy to operate

- Doesn’t require any special handling, training, or logistics

- Sensor can be connected directly to Particle Measuring System or third-party software

- Designed for continuous operation

Sterilization

a) Steam Sterilizers

Fedegari FVA/A1 Series

These sterilizers have been specifically designed and developed to meet the most rigorous application requirements in analytical and microbiology laboratories, research institutes, pharmaceutical and food industries as well as medical and hospital sectors.

- Validated operating software DCS PLUS 10 for total control of functional parameters

- Reduced operating costs thanks to optimized consumption and faster and more efficient processes

- Sanitary diaphragm valve in AISI 316 L stainless steel with pneumatical actuator for maximum reliability and tightness

- Patented lid seal with compressed air system

- Wide front door with safety lock for total and immediate access to the technical area

- Perfectly airtight, safe and extremely easy to maintain

- Vertical positioning of filters avoiding frequent rupture

Fedegari FVG Series

The FVG Series vertical steam sterilizers with built-in generator and air compressor are suitable for the sterilization in many different laboratory sectors.

- Exclusive horizontal swiveling lid with pneumatic gasket “rotate-n-seal”

- Built-in 316L stainless steel electric steam generator with automatic water feed pump

- Heat recovering system for water preheating to steam generator

- Dual sensor system, by pressure and temperature for double regulation and control of sterilization process

Fedegari FVS Series

The FVS series are suitable for standard sterilization in the laboratory field.

- Validated operating software TSC 09 microprocessor

- Built-in AISI 304 stainless steel recovery tank for steam condensates

- Exclusive swing-top opening lid with pneumatic gasket, quick closing and safety interlocks

- Portable type autoclave with 2 castors

- Microprocessor control system with graphic color LCD display

- Vertical positioning of filters avoiding frequent rupture

b) Autoclave

Fedegari FOB Series

It has been specifically designed and developed to meet the most stringent application requirements in analytical and microbiology laboratories, research institutes, the pharmaceutical and food industries, and in the medical and hospital sector.

- Validated operating software DCS PLUS 10 for total control of functional parameters

- Reduction in operating costs thanks to optimized consumption and better performance thanks to faster and more efficient processes

- Massive pressure vessels, pneumatic valves and hydraulic components made of high corrosion resistant 316 L sanitary stainless steel, sanitary grade

- Easy access to technical area for regular maintenance and emergency

- Unique opening/closing door system with patented pneumatic gasket seal

- Single or double hinged doors

- Vertical positioning of filters avoiding frequent rupture

Fedegari FOB4 Series

The use of first-class quality materials specially developed for the pharma industry guarantees the highest safety standards and consumption savings. These sterilizers have been specially designed with ergonomically features to easily handle the sterilization of large volumes.

- Validated operating software DCS PLUS 10 for total control of functional parameters

- Shortest batch times and optimum drying

- High efficient pre- heating/drying system guaranteed by the AISI 316 L stainless steel plate heat exchanger

- Full accessibility to technical area for easy maintenance

- Single or double vertical automatic sliding doors

- Display on loading and unloading sides

- Vertical positioning of filters avoiding frequent rupture

Fedegari FOB5 Series

FOB5 series floor cabinet steam sterilizers combine high-performance with the most advanced process technology. The use of first-class quality materials specially developed for the pharma industry guarantees the highest safety standards and consumption savings. These sterilizers have been specially designed with ergonomically features to easily handle the sterilization of large volumes.

- Thema4lab process controller engineered and prevalidated by Fedegari according to GAMP 5

- Shortest batch times and optimum drying

- High efficient pre -heating/drying system guaranteed by the AISI 316 L stainless steel plate heat exchanger

- Full accessibility to technical area (frontal and lateral) for easy maintenance

- Single or double vertical automatic sliding doors

- Display on loading and unloading sides

- Vertical positioning of filters avoiding frequent rupture