One Minute Read: Data traceability in cleanroom monitoring

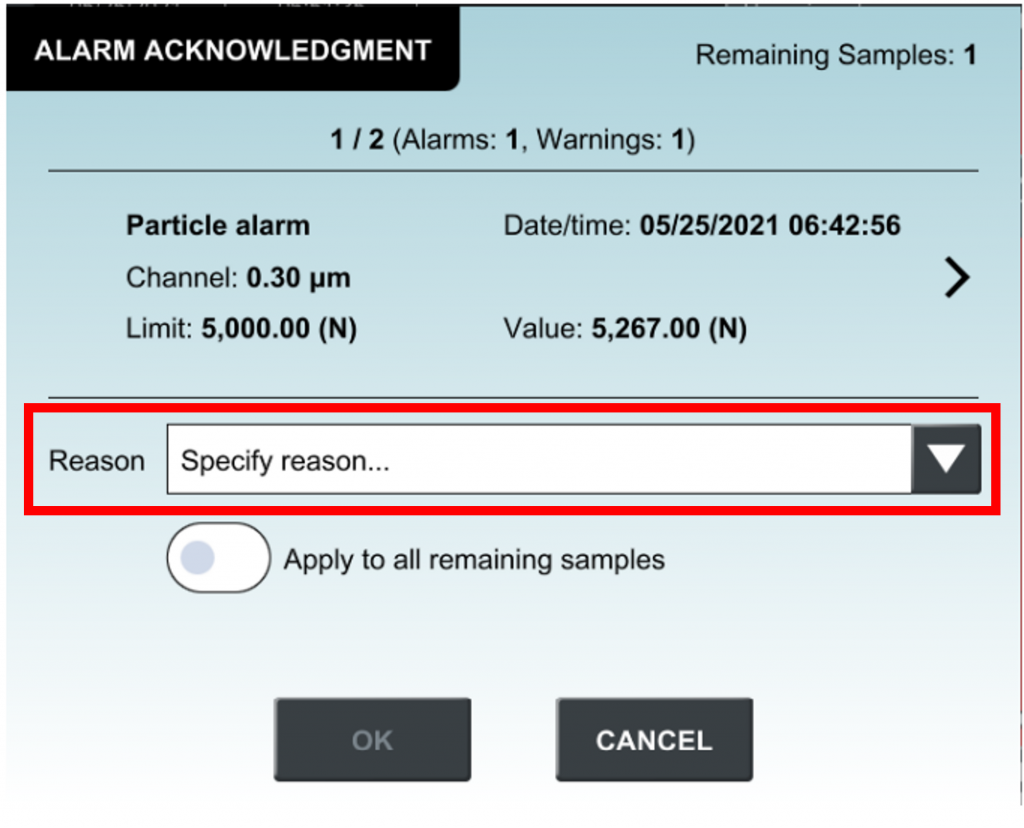

Documentation of data plays a crucial role in cleanroom monitoring. Other than serving as evidence in audit trail, the recorded data becomes critical when an abnormality is detected in a cleanroom as these recorded data would be needed by cleanroom operators to troubleshoot and diagnose the problem.

To find out what is happening when an abnormality is spotted, recorded data is traced to identify regular patterns and any suspicious particle event. It is also through this practice that a cleanroom monitoring plan could be reviewed and improved, leading to a much more efficient and cost-effective procedure.

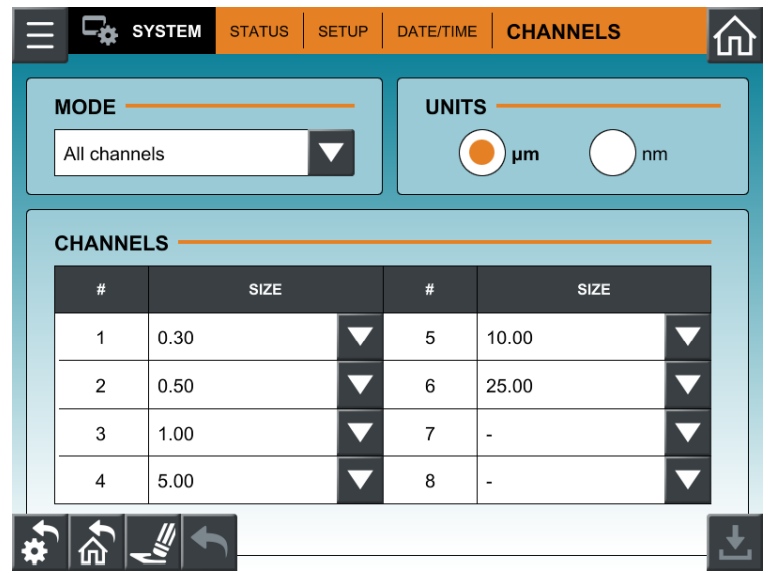

To facilitate these processes, Particle Measuring Systems (PMS) has designed and launched a new series of aerosol particle counter, the Lasair® Pro series, which can store up to 10,000 data samples. Moreover, the process of data investigation can be expedited as the Lasair® Pro series allows data filtering by location, date, and time, making search and export of specific recorded data quick and easy.